Nissan K24 Propane System Sensor: Upgrade and Maintainance

The Nissan K24 propane system has sensors to check and regulate the car’s propane fuel. These sensors are designed to control the propane pressure for safe engine operation.

Using propane rather than gasoline engines is more environmentally friendly and cost-effective for the K24 system. This guide explains the importance of the different types of Nissan K24 propane system sensors.

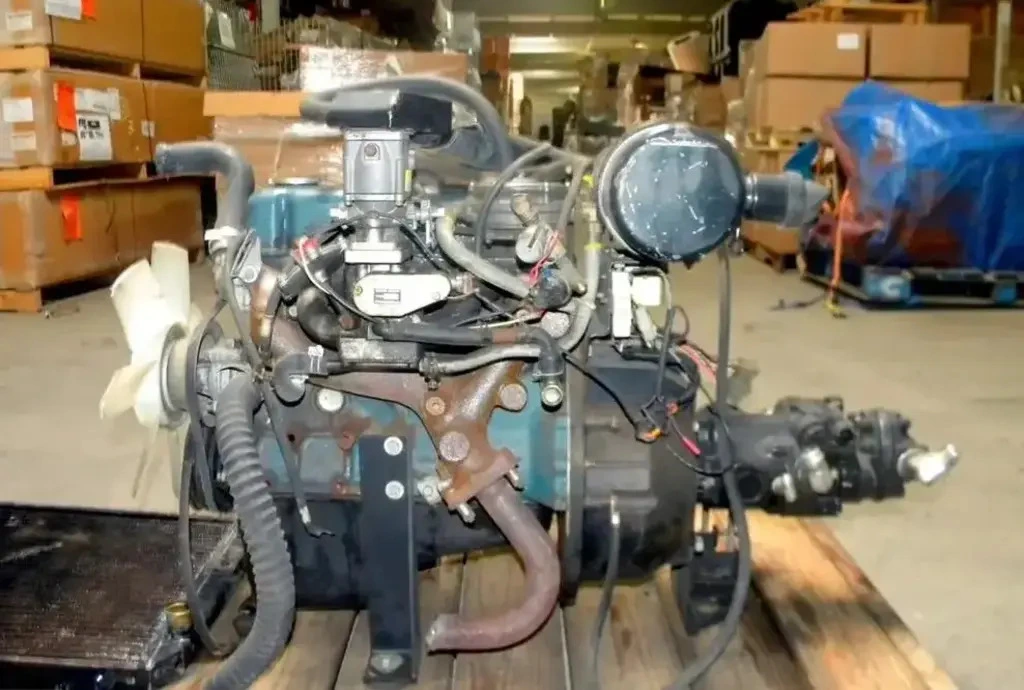

Nissan K24 Propane System

The Nissan K24 propane system is a fuel system that allows the vehicle to operate on propane instead of gasoline. Propane is a cleaner and cheaper fuel, so it is a good vehicle choice. The system contains special components such as a propane tank and sensors that monitor everything.

What Is a Propane System Sensor?

A propane system sensor is a device used in propane-powered vehicles or machinery. Its primary responsibility is monitoring the propane system and ensuring everything is operating properly. This sensor measures fuel levels, pressure, and temperature within the system. By tracking these conditions, the sensor helps prevent problems like fuel leaks and too much pressure.

If the pressure becomes too high, the sensor will inform the driver or alter the system to prevent harm. It also keeps in check that the engine operates smoothly by giving the appropriate amount of propane to the fuel injectors.

Specifications of Nissan K24 Propane Pressure Sensor

The Nissan K24 propane system sensor monitors propane levels and maintains smooth vehicle running through accurate pressure readings. It has a measurement range of 0-200 PSI and can withstand temperatures ranging from -40°C to 125°C. The sensor has a three-pin connector and outputs analog signals.

These standards make it dependable and effective for use in automobiles, as it provides precise monitoring and stability in many environments. Its sturdy construction provides peak performance, which will ultimately improve overall vehicle safety and efficiency.

Types of Nissan K24 Propane System Sensor

Propane systems are available in 3 major types. Each of these types has its special functions, such as:

- Pressure Sensors: Pressure sensors monitor the pressure inside the propane tank and fuel lines. They make sure that the system has the needed pressure for safe operation. If the pressure is too high or too low, the sensor informs the system to adjust to avoid risks or engine troubles.

- Temperature Sensors: Temperature sensors monitor the temperature of propane in the system. Propane can expand or contract in response to temperature. These sensors help maintain safe levels by regulating the flow or notifying the driver when temperatures increase too high.

- Level Sensors: Level sensors monitor the amount of propane remaining in the tank. This helps drivers keep track of fuel levels and avoid unexpected depletion. These sensors are important to make sure that the system does not run out of propane while in operation.

How to Calibrate a Propane Sensor?

Calibrating a propane sensor can be done easily with these steps:

1) Prepare the Equipment

First, get all the needed tools and equipment, such as a calibration gas with a specified amount of propane. Check the sensor’s handbook for specific calibration criteria and procedures. Make sure the vehicle or equipment is turned off and properly positioned.

2) Connect the Calibration Equipment

Follow the manufacturer’s instructions to attach the calibration equipment to the sensor. This means connecting a calibration gas bottle to the sensor’s input port. Make sure that all connections are secure to prevent leaks during the calibration procedure.

3) Carry out the Calibration

Turn on the calibration equipment and expose the sensor to the calibration gas. Follow the manufacturer’s instructions to change the sensor’s settings until it accurately reads the known propane concentration. This means tuning the sensor’s output using a calibration device or software.

4) Check Calibration Accuracy

After making modifications, compare the sensor’s readings to the known concentration of the calibration gas to maintain accuracy. To obtain precise results, repeat the calibration process as needed. Also, check that the sensor is within the manufacturer’s permitted calibration range.

5) Reinstall and Test

After the calibration, remove the calibration equipment and securely reconnect any removed components. Start the vehicle and check the sensor’s performance to confirm it functions properly. Test the system in normal operating conditions to check if the sensor gives accurate and reliable readings.

Problems You Could Face With the Propane Sensor

A propane system’s efficacy might be better than gasoline, but it doesn’t come without any trouble. There are also some problems you can face due to the propane sensor, such as:

Sensor Malfunction

The propane sensor can go out or malfunction due to heat or age. A malfunctioning sensor can produce incorrect results and give you inappropriate fuel management. This can cause performance issues such as low fuel efficiency and engine misfires.

False Alarms

A propane sensor can create false alarms and show problems such as leaks or low fuel levels when none exist. This could be a result of sensor sensitivity or calibration issues. False alarms can irritate and give you unneeded maintenance or repair actions.

Connection Issues

Loose or damaged cabling and connections can limit the sensor’s capacity to interact with the vehicle’s system. Poor connections can also cause the sensor to lose power or transmit inaccurate data, which can cause irregular performance or safety problems. Check connections regularly to prevent this issue.

Environmental Impact

Extreme environmental circumstances, such as hot or cold temperatures, can affect the sensor. These situations can cause the sensor to malfunction, resulting in delayed or inaccurate readings. Protecting the sensor from harsh environments can help it maintain its accuracy.

Calibration Errors

If the propane sensor is not properly calibrated, it can create inaccurate fuel values. This can result in wasteful fuel consumption and cause the engine to run lean or rich. Regular calibration must be done to make sure that the sensor produces correct data for optimal performance.

Calibration Drift

Even if a propane sensor was initially accurately calibrated, its accuracy can gradually decrease. This drift can result in incorrect fuel measurements and affect engine performance. Regular recalibration is required to ensure that the sensor operates accurately.

Contamination Issues

Dirt and dust residues can contaminate propane sensors and cause them to malfunction. Contaminants can also impair the sensor’s capacity to detect propane levels or pressures. To avoid contamination-related problems, you will need to keep the sensor and surrounding regions clean.

How to Maintain a Propane System?

Now, you know the problems you could face in a propane system, so how do you maintain it? Here is what you can do:

1) Regular Inspection

Check the propane system regularly for leaks and other signs of wear and tear. Check the hoses and connections to keep in check that they are in good shape. Finding errors can help you not face bigger problems and keep the system running securely.

2) Clean the Components

Clean the fuel injectors and other propane system components regularly to avoid dirt or residue buildup. Propane burns cleanly, but dust and debris from the surroundings can still contaminate the system. Keeping it clean improves performance and increases the life of the components.

3) Monitor Sensor Readings

Pay attention to the sensor data for pressure and fuel level. Sensors can warn you about problems such as low fuel or high pressure before they become major issues. Monitoring these sensors regularly helps to keep the system running smoothly and safely.

4) Replace Worn Parts

Hoses and valves in the propane system should be replaced as soon as they become old or broken. Over time, these pieces can decay and become less effective, which becomes a safety risk. Regular replacements help to keep the system in good functioning order.

5) Proper Propane Storage

Keep propane tanks in a cool, well-ventilated space away from direct sunlight and heat sources. High temperatures can increase pressure inside the tank and make you face safety risks. Safe storage extends the tank’s life and decreases the likelihood of mishaps.

6) Check for Rust and Corrosion

Check the propane tank and its components for rust or corrosion regularly. Rust can degrade the tank’s construction and compromise its safety and functionality. Clean or replace any compromised parts as soon as they show signs of corrosion.

7) Test the System for Leaks

Use soapy water or a leak detection solution to check leaks around connections and valves. Bubbles will show a leak that must be checked immediately. Regular leak checks will help prevent dangerous propane gas leaks and maintain proper operation.

8) Have Proper Ventilation

When using propane as fuel, ensure the vehicle or equipment has good ventilation. Poor ventilation can cause dangerous propane accumulation, while proper ventilation in the system will ensure that any unburned gas is safely dispersed.

How to Upgrade Your K24 Propane System?

Do you want to upgrade your K24 propane system? Here is how you can do it:

1) Install Advanced Sensors

Upgrade your pressure, temperature, and fuel level sensors to be more sensitive and accurate. Newer sensors give faster response times and better monitoring which allows more control over the propane system. This will give you more safety and more efficient engine performance.

2) Add a Propane Injection Kit

Try using a propane injection system to increase fuel delivery to the engine. These components help with a more accurate combination of propane and air which gives you higher engine power and better fuel economy. An updated injection system can also lower emissions and extend the engine’s life.

3) Upgrade to a Larger Tank

Switching to a larger propane tank is a good choice for longer driving distances. A larger tank can contain more fuel and end the need for refilling. This update is particularly useful for heavy-duty cars and long-distance driving.

4) Use High-Quality Fuel Injectors

Use high-performance fuel injectors made exclusively for propane. These injectors give better fuel atomization, which results in more efficient combustion. Upgraded injectors can increase engine power while improving overall system reliability.

5) Enhance the Fuel Management System

Upgrade the fuel management system to a more modern model that gives greater control over fuel supply. This device can alter the fuel mixture in real time based on driving conditions and has increased fuel efficiency and performance.

Conclusion

The Nissan K24 propane system Sensor is important for propane-powered cars to operate safely. The sensor improves engine performance by measuring pressure and fuel levels and ensures the environment isn’t damaged. Regular maintenance and modifications to the sensor can improve its reliability and prevent problems.

Investing in a properly operating propane sensor is important for optimizing the K24 propane system’s benefits, such as increased fuel economy and cost savings.

FAQs

Why Is My K24 Sensor Malfunctioning?

Your K24 sensor can malfunction due to reasons such as sensor wear, wiring issues, and junk buildup.

Is the K24 Propane System Efficient?

Yes, it has higher fuel efficiency and lower operational costs than standard gasoline engines.

Can Propane Be Run in a Gas Engine?

Yes, you can use propane in a gasoline engine. A converter kit is needed for best performance.

What Should Be the Fuel Pressure for Nissan Ka24?

For a Nissan Ka24, the fuel pressure should be a minimum of 34 psi and a maximum of 43 psi.